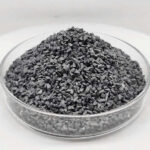

Alumina Zirconia Grit

Zirconia Fused Aluminum is a kind of high-grade raw material . Using natural zircon sand and bauxite as starting material, it is manufactured by high temperature melting and quenching crystallization. Because of the tough,dense micro-crystalline structure, high strength and good thermal physical, it is used to manufacture high-performance abrasives, abrasives and refractory products.This product has been declared national patent,and advanced high-tech product. It was also awarded the second prize of Scientific and Technological achievement by the Technology Department of Henan province. Typical Chemical Analysis Al2O3 Fe2O3 ZrO2 SiO2 TiO2 70.6% 0.25% 25.8% 0.85% 1.35% Physical Properties Color Grey Shape Blocks, tough and sharp Crystal Form Alpha-alumina and “a-Al2O3”+“Al2O3-ZrO2”combined tree system True Specific Gravity 4.55g/cm3 Melting Temperature About 1900°C Magnetic Material 0.0080% Bulk Density(g/cm3) 2.18 Products Show: