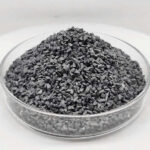

Zirconium Alumina 25%(ZA25)

Zirconium Aluminum is produced by fusing rich aluminum, zirconium materials and additives in electric arc furnaces, smelting with high temperature above 2250℃, cooling down with special technology, and compacting with Barmac process, which has the characteristics of tenacious texture, dense sturcture and high strength. According to the content of ZrO2, generally have low zircon corundum (10%~15% ZrO2),