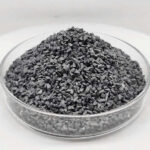

zirconia fused alumina main application

Zirconia Fused Alumina (ZFA) is a high-performance synthetic abrasive and refractory aggregate. It is a eutectic material created by fusing (melting together in an electric arc furnace) Alumina (Al₂O₃) and Zirconia (ZrO₂).