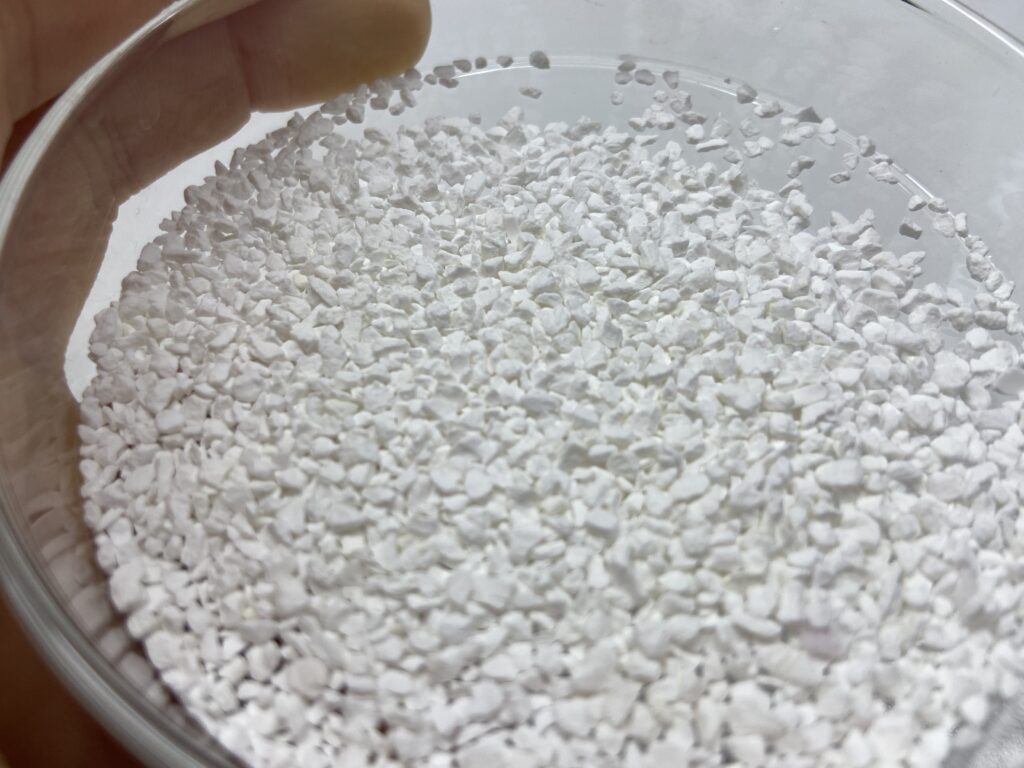

Introduction to Zirconia Toughened Alumina (ZTA)

Zirconia Toughened Alumina (ZTA) is an advanced ceramic composite that combines the high hardness and wear resistance of alumina (Al₂O₃) with the superior fracture toughness of zirconia (ZrO₂). By incorporating ZrO₂ particles into an Al₂O₃ matrix, ZTA achieves a unique balance of mechanical strength, thermal stability, and crack resistance, making it suitable for demanding engineering and biomedical applications.

1. Composition & Structure

Matrix: Alumina (Al₂O₃, 70-90 wt%) – provides hardness and chemical stability.

Toughening Phase: Zirconia (ZrO₂, 10-30 wt%) – enhances fracture toughness via phase transformation toughening.

Stabilizers (Optional): Y₂O₃, CeO₂, or MgO may be added to control ZrO₂ phase stability.

Microstructural Features:

Fine ZrO₂ particles (typically <1 µm) dispersed in the Al₂O₃ matrix.

Tetragonal ZrO₂ (t-ZrO₂) remains metastable at room temperature, enabling stress-induced phase transformation.

2. Key Properties & Advantages

| Property | ZTA | Pure Al₂O₃ | Pure ZrO₂ |

|---|---|---|---|

| Hardness (HV) | 1600-2000 | 1800-2200 | 1200-1400 |

| Fracture Toughness (K<sub>IC</sub>, MPa·m<sup>1/2</sup>) | 5-10 | 3-4 | 6-12 |

| Flexural Strength (MPa) | 500-1000 | 300-500 | 800-1200 |

| Thermal Shock Resistance | High | Moderate | Very High |

| Cost | Moderate | Low | High |

Why Choose ZTA?

✔ Higher toughness than Al₂O₃ (less brittle, more impact-resistant)

✔ Higher hardness than ZrO₂ (better wear resistance)

✔ Good thermal & chemical stability (suitable for harsh environments)

✔ Cost-effective alternative to pure ZrO₂

3. Toughening Mechanisms

ZTA’s improved fracture resistance is due to:

Transformation Toughening

Under stress, tetragonal ZrO₂ (t-ZrO₂) → monoclinic ZrO₂ (m-ZrO₂) phase transition occurs, causing ~4% volume expansion.

This creates compressive stresses around crack tips, hindering crack propagation.

Microcrack Toughening

ZrO₂ phase transformation induces microcracks, which absorb energy and deflect main cracks.

Residual Stress Effects

Thermal expansion mismatch between Al₂O₃ and ZrO₂ generates beneficial residual stresses.

4. Applications of ZTA

Due to its balanced properties, ZTA is used in:

(1) Cutting Tools & Wear Parts

Inserts for machining, grinding media, wire drawing dies.

Superior to Al₂O₃ in impact resistance.

(2) Biomedical Implants

Hip & knee joint replacements (alternative to pure ZrO₂).

Dental crowns and implants.

(3) Industrial & Structural Components

High-temperature bearings, seals, valves.

Ballistic armor (better toughness than Al₂O₃).

(4) Electronics & Energy

Substrates for sensors, insulators.

Components in solid oxide fuel cells (SOFCs).