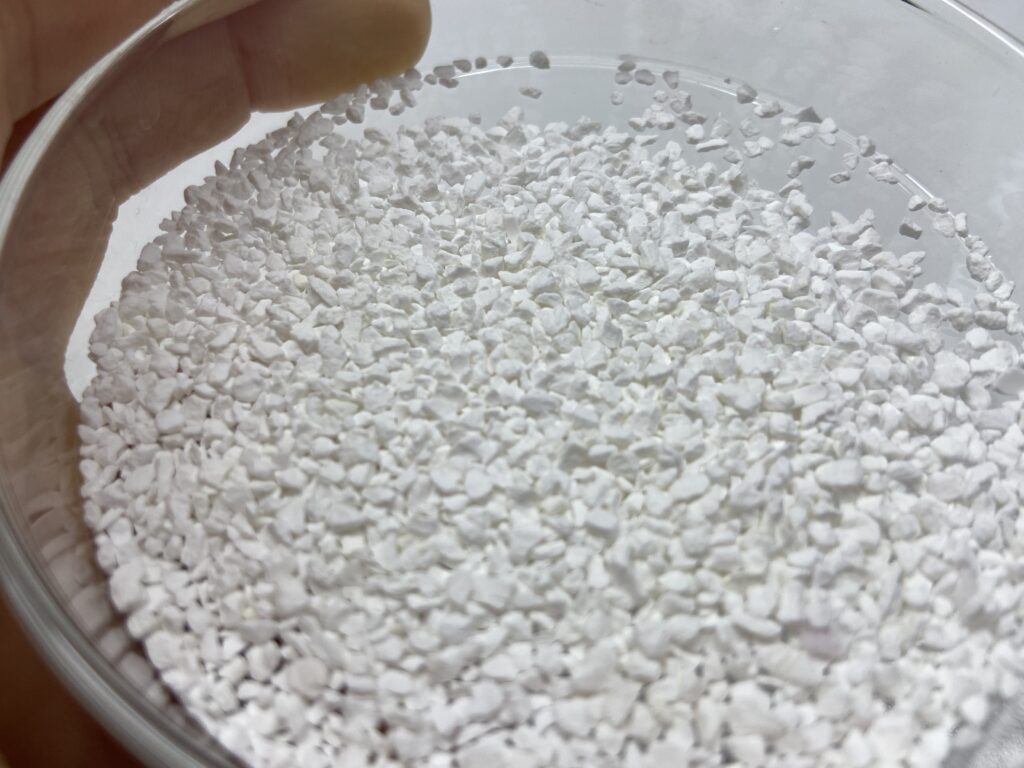

Zirconia-toughened alumina (ZTA) is a high-performance ceramic composite that combines the hardness and wear resistance of alumina (Al₂O₃) with the fracture toughness of zirconia (ZrO₂). This combination results in a material with superior mechanical properties, making it suitable for demanding applications in various industries. Below are key details about ZTA and its applications:

1. Composition & Properties

Alumina (Al₂O₃): Provides high hardness, wear resistance, and thermal stability.

Zirconia (ZrO₂): Enhances toughness by undergoing stress-induced phase transformation, which absorbs energy and prevents crack propagation.

Typical Composition: 10-20% ZrO₂ in an Al₂O₃ matrix.

Key Properties:

High fracture toughness (compared to pure alumina)

Excellent wear resistance

Good thermal and chemical stability

High strength and hardness

2. Applications of Zirconia-Toughened Alumina (ZTA)

A. Medical & Dental

Orthopedic Implants (e.g., hip & knee joints) – due to biocompatibility and wear resistance.

Dental Implants & Crowns – improved strength and aesthetics compared to pure zirconia or alumina.

B. Industrial Wear Parts

Cutting Tools & Inserts – enhanced toughness for machining applications.

Wire Drawing Dies – resists abrasive wear.

Pump Seals & Bearings – withstands harsh environments.

C. Defense & Armor

Ballistic Armor (body armor, vehicle protection) – improved impact resistance due to energy absorption from zirconia phase transformation.

D. Electronics & Engineering

Semiconductor Components – used in high-wear environments.

Precision Engineering Parts – where dimensional stability is critical.

E. Automotive

Valve Seats & Guides – resists wear in high-temperature engine environments.

Sensor Components – for harsh exhaust environments.

3. Advantages Over Pure Alumina or Zirconia

Higher toughness than pure alumina (less brittle).

Better wear resistance than pure zirconia.

Cost-effective compared to fully stabilized zirconia.